Materials.

Our expertise spans the entire industrial lifecycle, from upstream research to production.

We get involved from the R&D phase for the development of innovative materials, as well as supporting material selection in production, in close collaboration with suppliers.

Our consultants act as technical specifiers and guarantors, ensuring the qualification, reliability, and compliance of material solutions with functional, regulatory, and industrial requirements. Our support also includes experimental characterization, testing, process development, quality control, and securing critical supply chains.

Development of materials, processes, and surfaces.

- Development and qualification of new materials or processes (metallic, composites, foams, wood, ceramics, heat treatments, additive manufacturing, surfaces, resins, etc.).

- Development and characterization of surface treatments: anodizing, cadmium plating, passivation, chemical conversion, thermal spraying, etc.

- Material functionalization.

- Light-matter interaction (laser parameters, surface property modification, nanostructuring).

Material behavior, assemblies, and modeling.

- Behavior studies (fatigue, corrosion, aging, etc.) and calculation-to-test correlation.

- Advanced modeling of mechanical, thermal, thermo-mechanical, or physico-chemical behavior.

- Fatigue and damage tolerance calculations.

Testing.

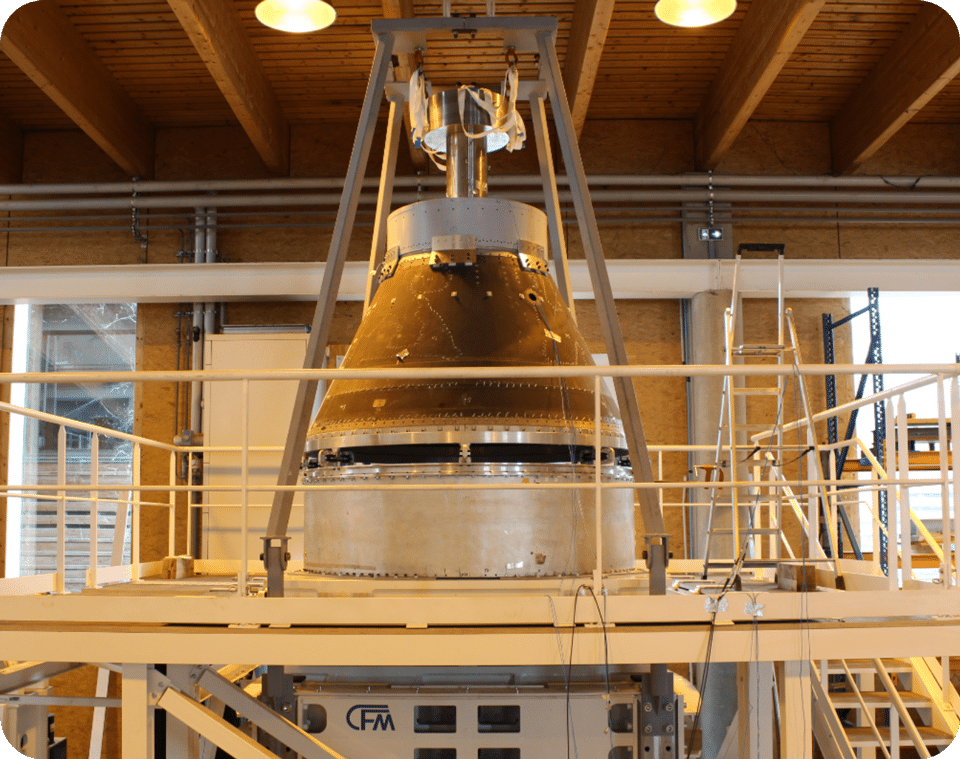

- Execution of mechanical tests (tension, compression, shear, fatigue, etc.) on specimens, subassemblies, and complete structures.

- Execution of environmental tests: corrosion (salt spray, filiform), fluid resistance, and climatic aging.

- Vibrational, acoustic, and radiofrequency characterization of materials and systems.

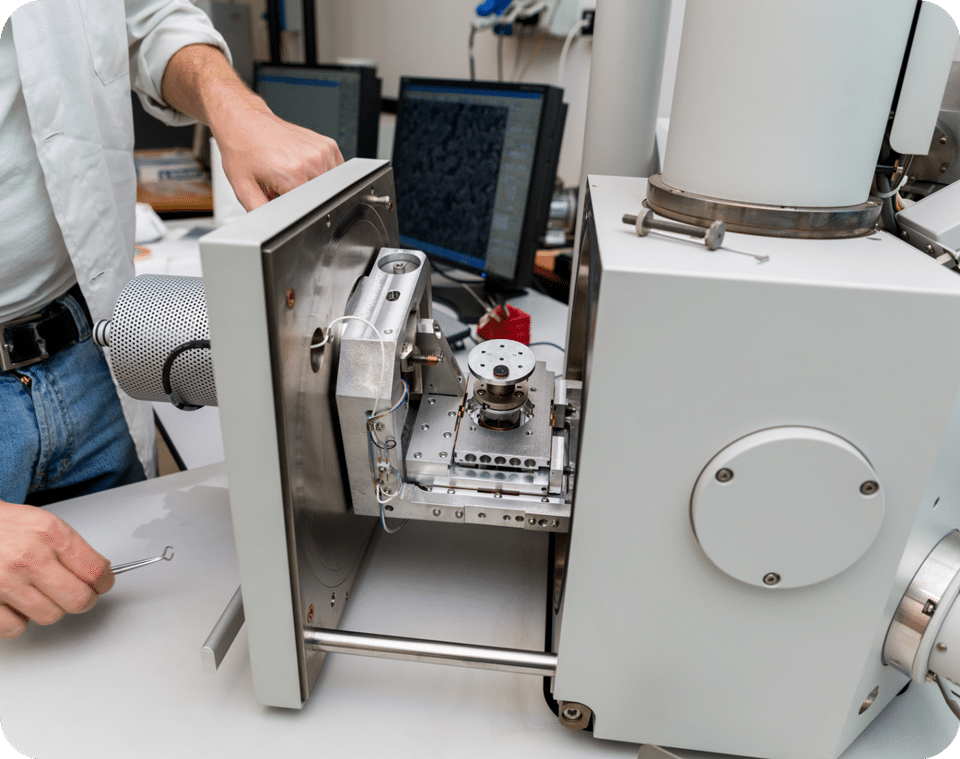

- Conducting metallographic and microstructural analyses (optical, SEM, EDS, 3D microscopy).

Environment, Quality, and Continuous Improvement.

- Regulatory monitoring (REACH, RoHS, etc.) and obsolescence management.

- Industrial qualification of suppliers, audits.

- Securing the material supply chain and supporting production.

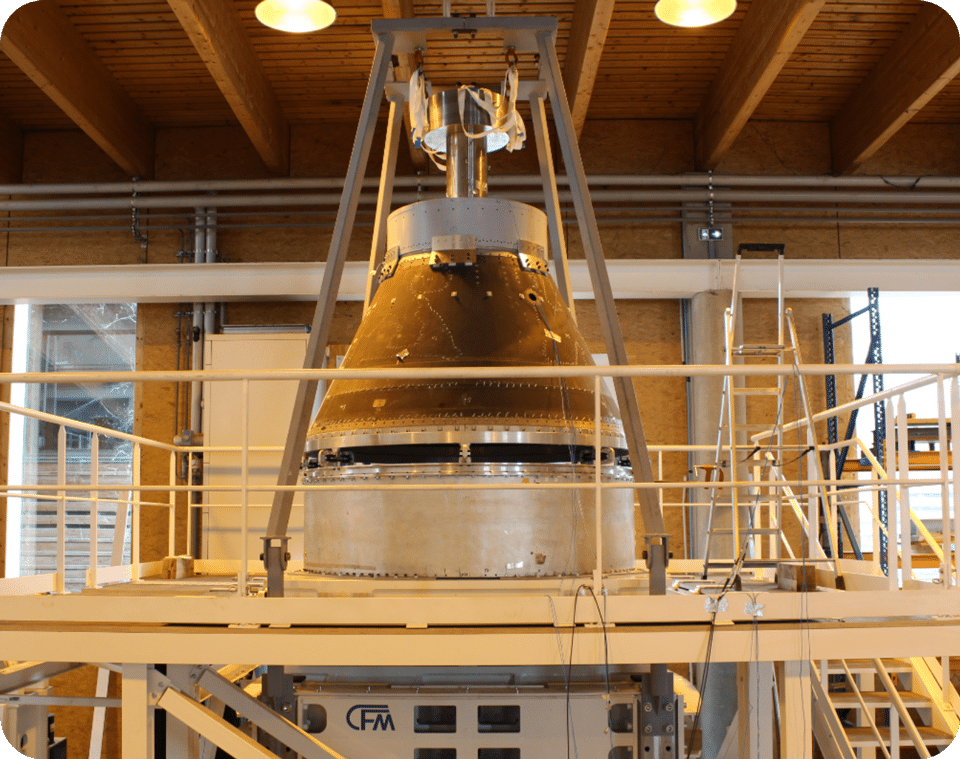

Test benches.

Examples of projects: damping measurement bench for composite materials, erosion test bench, bending bench for weld characterization, drop test bench.

- Custom design of test benches.

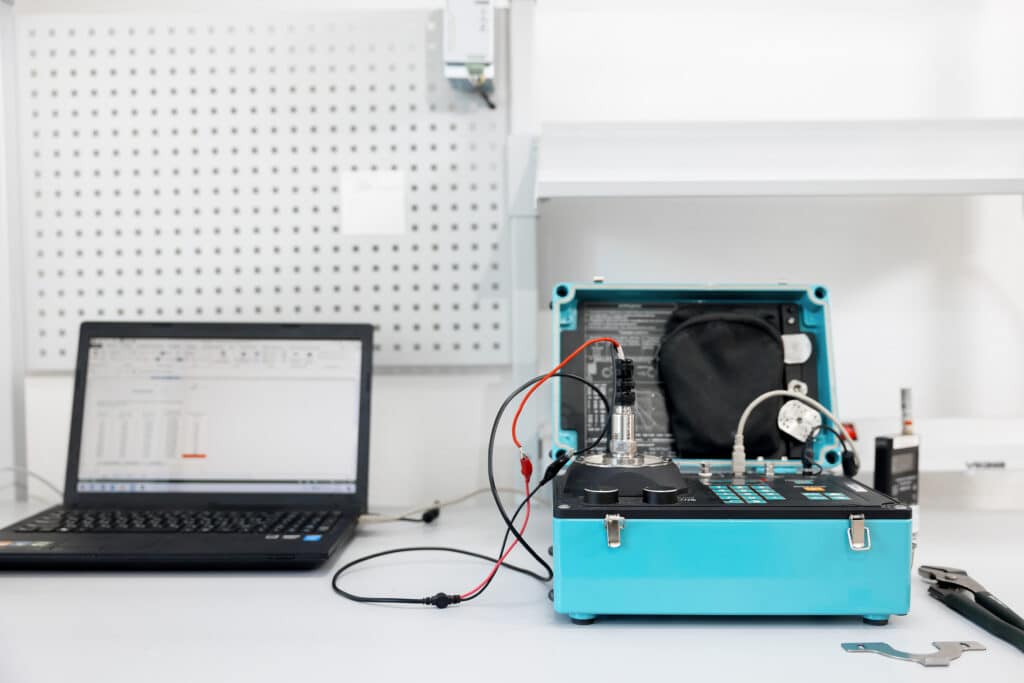

- Implementation of automation with control interface and safety features.

- Adaptation or modification of existing test benches.

- Commissioning, functional validation, and user training.

Examples of projects: damping measurement bench for composite materials, erosion test bench, bending bench for weld characterization, drop test bench.

Qualification.

- Preparation and monitoring of qualification tests for new materials and associated surface treatments: test program definition, supervision of specimen manufacturing, planning and monitoring of tests (mechanical, climatic, electrical, fatigue, salt spray…).

- Drafting of qualification reports.

- Justification and certification for fatigue and damage tolerance.

They trust us.