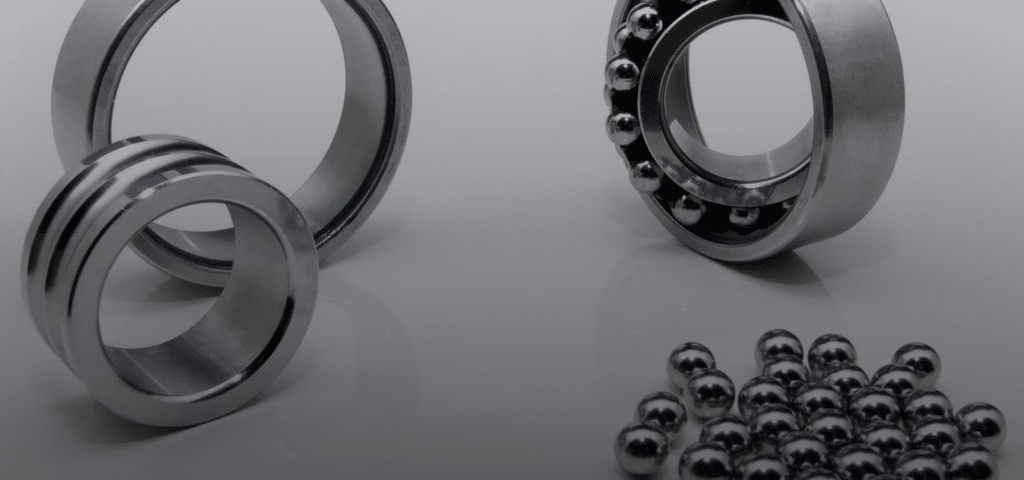

Mechanics.

Our expertise is built on mastery of design, digital simulation, and testing, which we apply at every stage of your product development cycle.

We work in structural mechanics, fluid mechanics, acoustics, and vibrations, providing solutions tailored to the technical and functional challenges of each project.

Through a rigorous technical approach and a strong culture of innovation, we deliver reliable solutions to the most complex mechanical challenges, in demanding, high value-added environments.

Through a rigorous technical approach and a strong culture of innovation, we deliver reliable solutions to the most complex mechanical challenges, in demanding, high value-added environments.

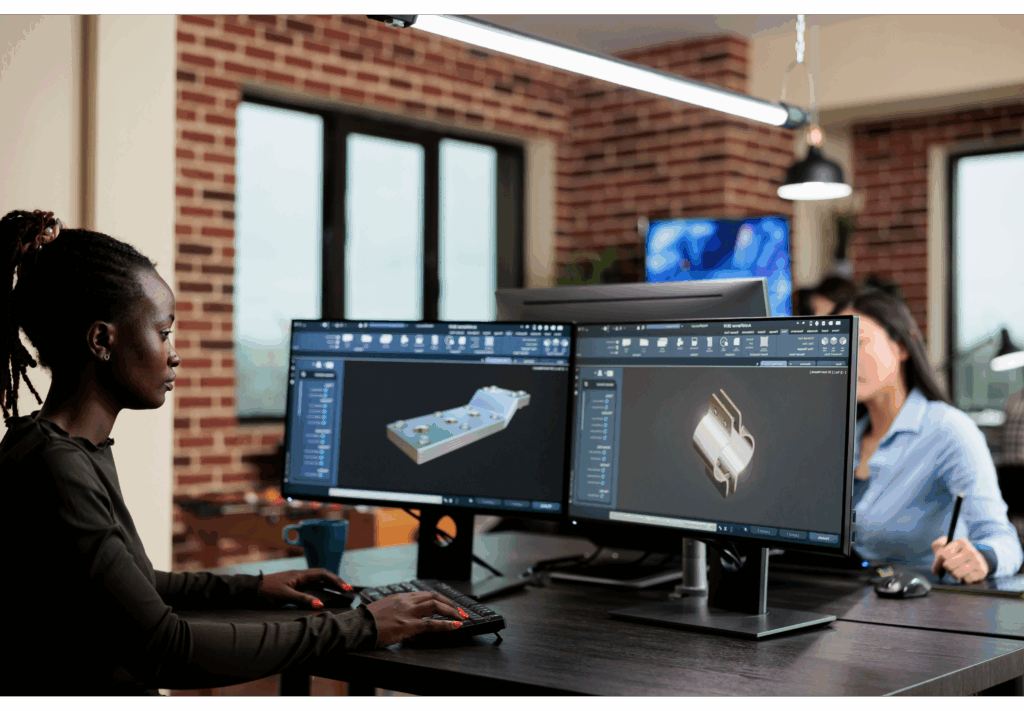

Structural analysis and mechanical design.

- Digital modeling: CAD design, drafting, creation of parametric or adaptive models, implementation of multi-scale or multi-body models.

- Structural analyses: static, dynamic, impact, vibration, and non-linear calculations, as well as thermo-mechanical simulations.

- Fatigue analysis and damage tolerance assessment to estimate the service life of structures and ensure their operational integrity.

- Development of advanced calculation methodologies.

- Handling of technical waivers and involvement in the justification of non-conformities.

- Design and manufacture of demonstrators or prototypes to validate technical choices.

- Preparation of technical drawings, writing of calculation reports, and justification of sizing.

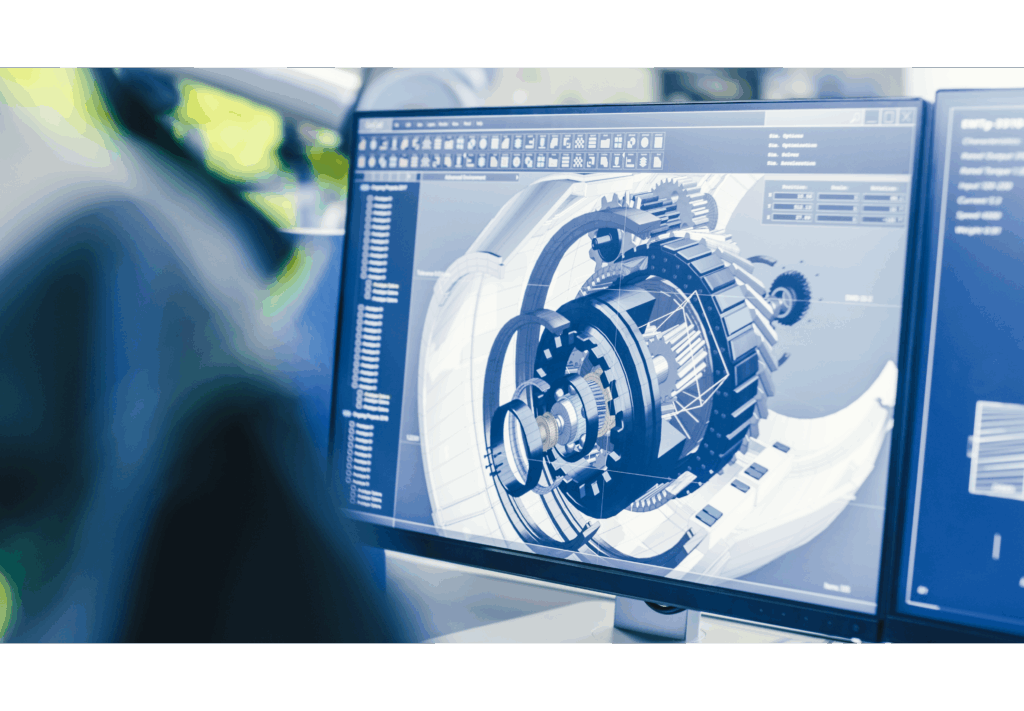

Vibrational analysis.

- Linear and nonlinear calculations based on transient or steady-state excitation : shock, seismic, harmonic, random.

- Modal analyses: extraction of natural frequencies, mode shapes, and damping assessment.

- Vibration fatigue analysis and estimation of service life under severe vibrational environments.

- Development of vibration damping systems.

- Vibration testing on shaker tables or multi-axis exciters (hydraulic or electrodynamic).

- In-flight vibration testing with multi-sensor instrumentation.

Fluid mechanics.

- Aerodynamic studies of internal flows (fuel circuits, cooling systems, complex ducts) and external flows (fuselages, nacelles, air intakes) on vehicles and propulsion systems.

- Numerical simulations in aeroelasticity: fluid-structure coupling, flutter analysis, and unsteady dynamic responses.

- Thermal analyses: heat transfer by conduction, convection, and radiation; sizing of thermal protection; thermal management of onboard subsystems.

- Fuel system studies: filling, draining, pressurization, cavitation, transient behavior, and fluid-material compatibility.

- Inerting studies: characterization of systems for reducing flammability and optimization of inerting times.

- Coupled multiphysics studies: fluids, thermal, and mechanical analyses to predict complex behaviors in constrained environments.

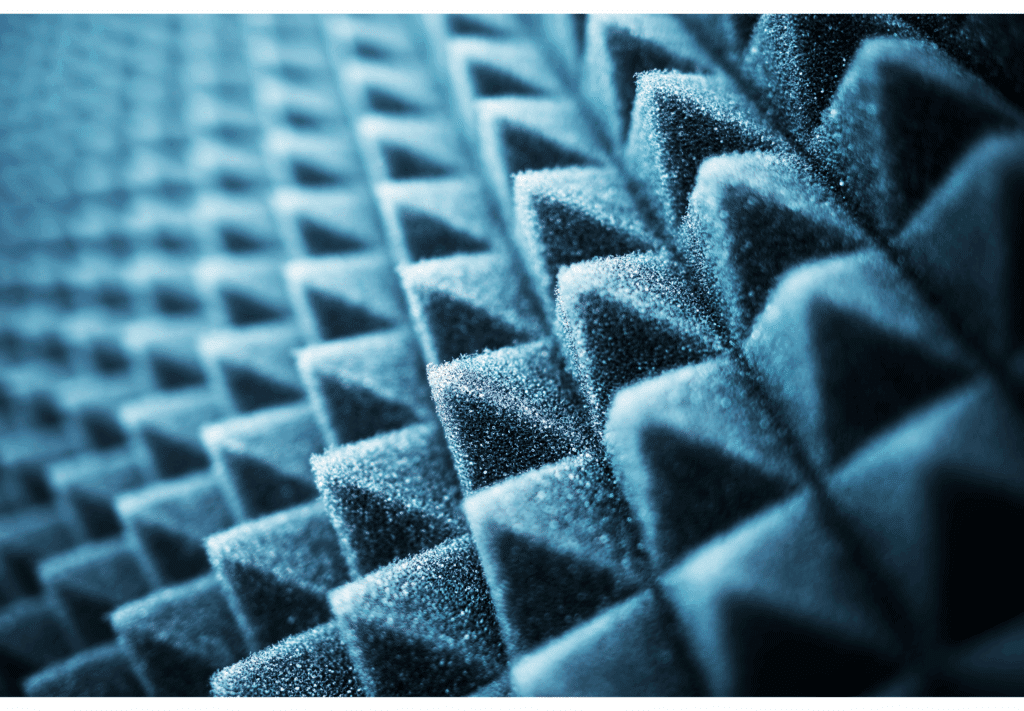

Acoustics.

- Acoustic impact studies: on-site measurements, diagnostics, and technical recommendations.

- Internal acoustic and vibroacoustic comfort analysis: evaluation of interior noise on all types of vehicles (aircraft, helicopter, train, etc.), source identification, simulation, testing, and definition of acoustic treatments.

- Aeroacoustic simulations: prediction of the acoustic signature of aircraft and turbomachinery (CFD/CAA coupling).

- Development of new acoustic calculation methodologies.

- In-flight acoustic testing: instrumentation, data analysis with signal processing (filtering, frequency analysis, signature extraction, time-frequency processing).

- Development of acoustic and thermoacoustic test benches.

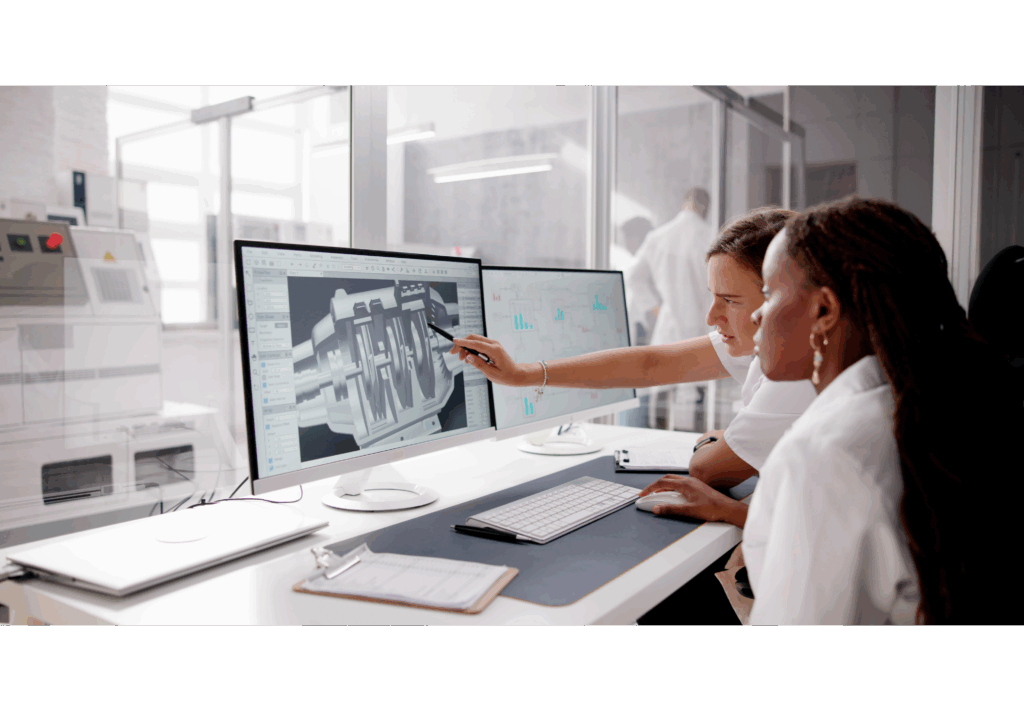

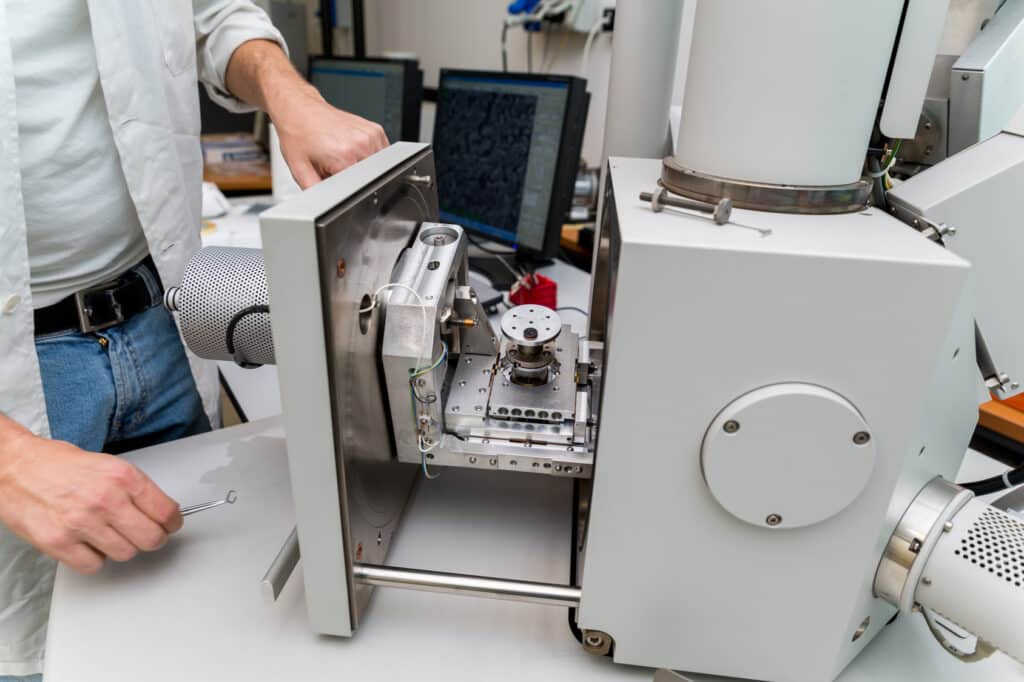

Qualification testing.

- Management of comprehensive qualification and acceptance test campaigns for assemblies (hydraulic, pneumatic, mechanical, acoustic, etc.): definition of test programs (DO-160, MIL-STD, etc.); preparation and execution of tests; setup of specialized tools and instrumentation; writing of qualification reports.

- Management of qualification tests on 6-axis vibration platforms.

Test benches.

Examples of projects: rotary bending test bench for electrical harnesses, qualification test bench for vibration isolation systems, qualification bench for oil level gauges.

- Custom design of test benches.

- Implementation of automation with control interface and safety features.

- Commissioning, functional validation, and user training.

- Test benches for specific vibration, acoustic, environmental, or mechanical testing.

Examples of projects: rotary bending test bench for electrical harnesses, qualification test bench for vibration isolation systems, qualification bench for oil level gauges.

They trust us.